Llama a+86 018059983973

Envíenos un correo electrónicomarketing@gester-instruments.com

Máquinas GESTER para EN388 2016: Guantes de protección contra riesgos mecánicos

EN 388:2016 Descripción general

EN 388 es una de las normas europeas más comunes para

Prueba de guantes de protección contra riesgos mecánicos en aplicaciones de la industria general.

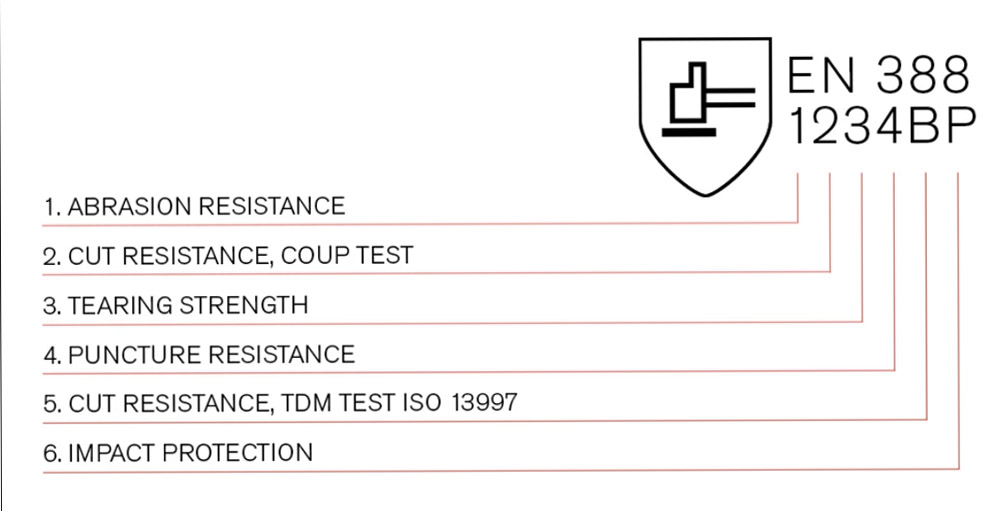

EN 388 incluye cuatro pruebas de rendimiento: resistencia a la abrasión, resistencia al corte de cuchilla, resistencia al desgarro y resistencia a la perforación.

El rendimiento del guante se clasifica según cuatro o cinco niveles de rendimiento. El usuario final puede seleccionar un guante con un perfil de rendimiento adecuado para una actividad laboral específica. Por ejemplo, un guante podría tener un nivel de rendimiento 4 para la abrasión y un nivel 1 para el desgarro (en las normas europeas, cuanto mayor sea el número, mayor será la protección).

Pruebas según EN 388:2016

Muestreo y acondicionamiento

Equipo GESTER:

Cámara de prueba de temperatura y humedad programable GT-C52

Capacidad: 80L o 150L (elija uno)

Rango de humedad: 20% ~ 98%

Rango de temperatura: -20~150°C

Fuente de alimentación: 1∮ CA 220 V 50/60 Hz

Accesorios estándar: Vídeo de funcionamiento, Certificado de calidad, Manual de funcionamiento en inglés.

Abrasión

Se cortan muestras de la palma de un guante y se frotan contra un papel abrasivo con una máquina de abrasión tipo Martindale. Se mide el número de ciclos necesarios para perforar las muestras. El nivel de protección se expresa en grados del 1 al 4 y depende del número de revoluciones necesarias para que se produzca un agujero en el material. Cuanto mayor sea el número, mayor será la resistencia a la abrasión.

Probador de abrasión Martindale GT-KC13B

Cumple con la norma EN388.

Posición de prueba: 4

Modo de control: control PLC y pantalla táctil

Accesorios estándar: Peso de abrasión y soporte (1 juego), Peso de pilling y soporte (1 juego), Tela abrasiva estándar (2 piezas/cabezal), Espuma de respaldo estándar de 38 mm (60 piezas), Discos de fieltro tejido estándar de 140 mm (2 piezas/cabezal), Discos de fieltro tejido estándar de 90 mm (2 piezas/cabezal), Fotografías (copia una), Plantilla de corte de muestra (D 38/90/140 mm, cada una 1 pieza), Peso de prensado (1 pieza), Cargador de muestra en forma de cuenco (1 pieza), Bola de acero (3 piezas), Cable de alimentación (1 pieza), Manual en inglés, Certificado de calidad.

Corte de cuchilla

Se toman muestras de la palma de un guante y se registra el número de ciclos necesarios para cortar el espesor completo de la muestra mediante una cuchilla circular giratoria. El filo de la cuchilla varía y se evalúa utilizando la máquina de prueba de corte para cortar un tejido de referencia estándar. La resistencia al corte del guante se basa en un índice relativo que compara el número de ciclos necesarios para cortarlo con el tejido estándar. La norma EN 388 define cinco niveles de rendimiento, desde el nivel 1 (índice de corte > 1,2) hasta el nivel 5 (índice de corte > 20).

Probador de corte para parte superior de guantes y zapatos de seguridad GT-KC29

Carrera: 50 mm

Carga: 50 ± 0,5 N

Portamuestras: 2 juegos

Hoja circular: Diámetro 45 ± 0,5 mm, Grosor 0,3 mm, Ángulo de corte 30° ~ 35°

Velocidad máxima de corte: 10 cm/s de velocidad lineal

Contador: Pantalla LCD, 0-99.999.999

Fuente de alimentación: CA 220 V 50/60 Hz

Normas: EN 388 sección 6.2, ISO 20344 sección 6.14, GB/T 20991 sección 6.14, AQ 6102 sección 4.3.2, AS/NZS 2210.2 sección 6.14

Accesorio estándar: Portamuestras (juego de 2), cuchilla circular (1 pieza), papel de aluminio (1 rollo), papel de filtro (1 pieza), cable de alimentación (1 pieza).

Lágrima

Se toman muestras de la palma de un guante, como las de la pernera del pantalón, y se rasgan utilizando una máquina de ensayo de tracción estándar. La norma EN 388 define cuatro niveles de rendimiento, que van desde el nivel 1 (resistencia al desgarro > 10 N) hasta el nivel 4 (resistencia al desgarro > 75 N).

Probador universal GT-K01 para perforaciones y desgarros

Prueba

eh

(Modelo de control por computadora de doble columna)

Capacidad máxima: 5 kN

Célula de carga: La marca de EE. UU.

Velocidad de prueba: 0,001-1000 mm/min

Pantalla: Modo de visualización de la computadora

Resolución de fuerza: 1/100.000

Precisión de fuerza: ≤+/-0,5%

Resolución de carrera: 0,001 mm

Resolución del extensómetro: 0,001 mm

Normas: EN 388

Accesorio estándar: mordazas de tracción planas GT-KE22 (1 juego), software de operación en inglés (1 pieza), cable de conexión con PC (1 pieza), extensómetro (1 juego), línea de alimentación (1 pieza).

Punción

Se toman muestras de la palma de un guante y se mide la fuerza necesaria para penetrarla con una aguja definida mediante un comprobador de compresión y perforación de calzado de seguridad. La norma EN 388 define cuatro niveles de rendimiento, desde el nivel 1 (fuerza de perforación > 20 N) hasta el nivel 4 (fuerza de perforación > 150 N).

Equipo GESTER:

Probador de compresión y perforación de calzado de seguridad GT-KB12A

Capacidad máxima: 30 kN

Resolución de fuerza: 1/10000

Precisión de fuerza: ≤+/-0,2 % FS

Rango de carrera: 0-300 mm

Resolución de trazo: 0,01 mm

Carga de compresión: 15 KN o 10 KN

Clavo de prueba: Ø4,5 mm

Velocidad de compresión: 5 ± 2 mm/min

Fuente de alimentación: 1∮ CA 220 V 50/60 Hz

Normas: EN 388 sección 6.4

Accesorio estándar: Platina (1ud.), Clavo de prueba (1ud.), Software de operación, Cable de alimentación (1ud.), Abrazadera inferior EN 388 para comprobador de punciones (dimensión interior 20mm).

Protección contra impactos

Excepto en los dedos, en cada zona donde se declare protección contra impactos se deberá comprobar la atenuación del impacto midiendo la fuerza máxima transmitida. Para cumplir los requisitos, esta fuerza debe ser inferior a un valor definido.

Aplicación de la norma EN 388:2016

La norma EN 388 especifica los requisitos y métodos de ensayo para guantes de protección contra riesgos mecánicos. Esta norma abarca todo tipo de guantes de protección contra riesgos mecánicos. Los sectores de aplicación típicos incluyen: